Enabling Works | Demolition | Remediation | Civils Works

South Tyneside Council

£20m

Ongoing

Location & Overview

Preparing a 9ha former dockyard site on the south bank of the River Tyne for mixed-used development; including marine civils, demolition, bulk earthworks and land remediation.

The transformation of the dilapidated industrial brownfield site by demolishing and removing redundant structures, installing sheet piles into the River Tyne, addressing contamination issues, and re-grading the site layout.

Works & Solutions

Works on the site involved clearance, demolition of a large retaining wall and removal of marine structures and underground obstructions; together with earthworks, processing of site-won materials and drainage works.

Utilities isolation and removal was undertaken before the demolition of the dilapidated dock infrastructure was removed along with the timber jetties, steel structures and suspended concrete quay.

Dock No. 4 was sealed, dewatered and infilled with gravel. Repairs to dock nos. 1-3 and a high-quality public realm space created.

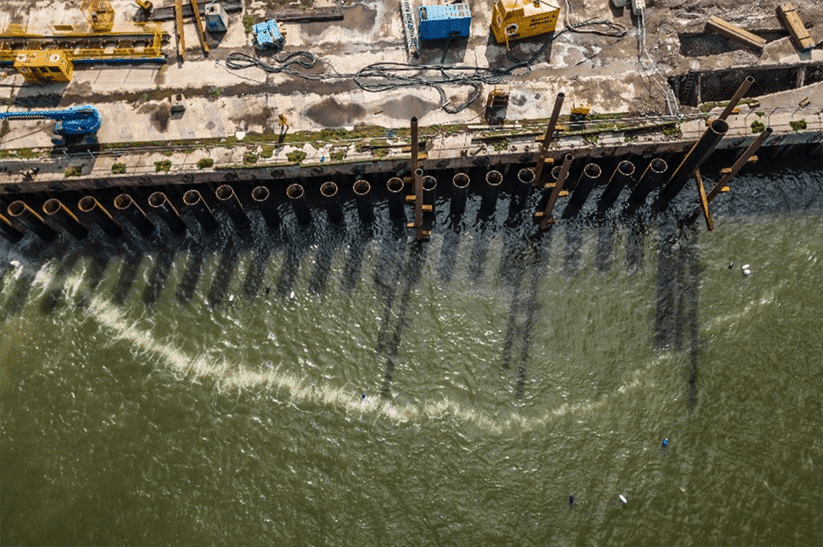

Installation of sheet pile walls, temporary dock-closing structure and combi pile walls, together with hard and soft landscaping.

Demolition

Demolition of an 8m high, 400m long two-tier concrete retaining wall that ran through site, splitting it into two levels, creating a 6-7m difference between the upper and lower zones of the site.

Earthworks

Earthworks were required to redistribute earth from the upper parts of the site to the lower level (93,000m³ cut and fill). Material from the demolished wall was crushed, screened and tested for chemicals to determine if it could be reused on site or as fill in dock no. 4. Upon completion, this earthworks operation formed a gentle slope down towards the River Tyne making the site more suitable for follow-on development.

Remediation

The brownfield site posed some complex and challenging problems associated with its historical use. Contaminated soil was treated via bioremediation with stabilisation/solidification (S/S) and retained for reuse on site under the CL:AIRE DoWCoP.

We carefully considered how to design and infill the dock, this was a delicate operation as the sediment at the base of the dock contained tributyltin (TBT), a biocide that was historically added to dock walls to prevent build-up of barnacles and is toxic to marine life.

Our dock infill programme was designed to prevent TBT’s, which are toxic to marine life, from seeping into the marine environment. The bottom layer of the dock was made up of original contaminated silt and reused granular material taken from the upper levels of the site. The silt and granular materials were blended together in a lined lagoon and then placed back into the dock. The rest of the dock was built up with other materials, all of which were tested and classified to ensure compliance with the local planning authority’s agreed remediation requirements.

River Wall Works

We built a new quay wall by driving piles into the riverbed. The new wall is 1.8m higher than the old failing quay edge wall, enabling the site to be raised to overcome serious flooding issues. Three of the docks are to be restored to preserve the area’s industrial heritage.

filling

We were responsible for the stabilisation / filling of the former dock, measuring 185m by 25m by 11m deep, with site-won material.

Detailed geological and hydrogeological assessments were undertaken of the ground, both within and adjacent to the river and former dock. This included scientifically robust site-specific performance information obtained through laboratory and on-site trials, relating to the materials placed / compacted within the dock. This allowed us to model the potential risk both during and after the remediation/earthworks phase. Our solution was adopted as the permanent solution for the site and the follow-on construction works.

Achievements

We faced restricted hours for piling works, which would have added time and cost to the project. With the Environment Agency’s agreement, we became the first company in the UK to successfully deploy an acoustic ‘bubble curtain’ alongside the piling works.

The curtain, designed and installed by Frog Environmental, was made up of 90m perforated, weighted tube laying on the riverbed, through which compressed air is forced. This creates a vertical chain of bubbles which mitigates the passage of noise from the source to the receptor. This novel solution protected passing fish from site noise, satisfying the MMO Licence conditions and allowing us unrestricted working. Watch the video to find out more.

The works are currently ongoing and we are supporting local charities including donations to South Shields FC Foundation.

Innovative approach to marine protection using an acoustic barrier.

We scored a very impressive 43/45 on the first Considerate Constructors Scheme visit.

Works being completed using in-house resources and plant.